Cutting-edge renewable energy systems that

can process a variety of organic substances with high efficiency

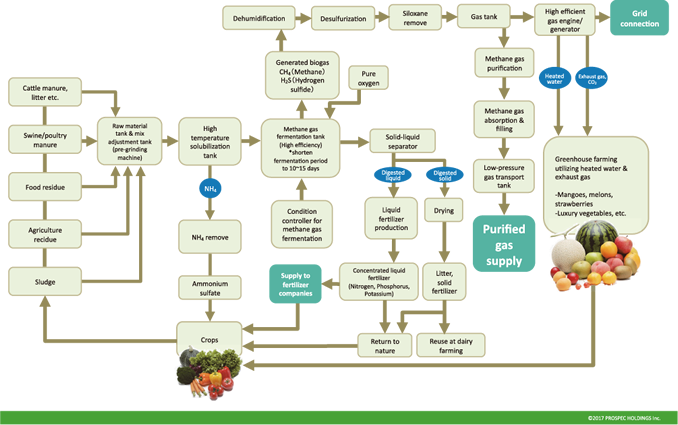

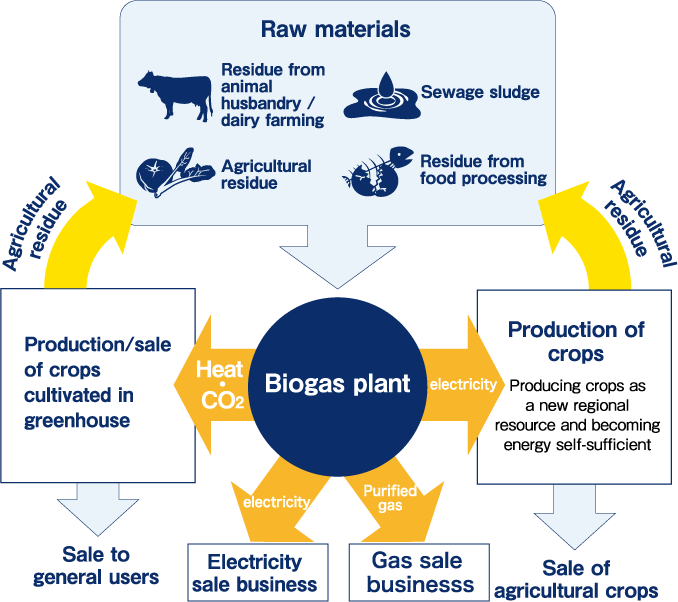

PR-AZ has developed a new biogas power generation system which targets the fields of dairy farming and agriculture. This is an innovative system with a great deal of business potential that is capable of reducing various environmental impacts.

This ingenious power generation system offers not only solutions to some of the issues that farmers face; it can also turn those issues into new business opportunities. It is also a recycling system that uses waste from the local community, in keeping with the principle of “local production and local consumption.”

Features

- Shortening fermentation period and increasing gas generation rate

-

Fermentation period is greatly shortened by high temperature fermentation system which utilizes solubilization tank. Gas generation rate is more than doubled comparing to existing facilities.

- No

Waste -

After advanced solid-liquid separator, solids are reused as litter etc., and all digested liquid is used as liquid fertilizer. Ammonium Sulfate (by-product) is also able to be utilized.There is no waste accordingly.

- Purified methane

gas supply -

Not only biogas power generation, but also gas supply with special purification & gas filling equipment is possible.

- Reuse of energy

and resources -

“Low cost” & “eco-friendly”

circular agriculture that reuses waste heat, emitted CO2, Ammonium Sulfate and liquid fertilizer from biogas plant can be realized.

Structure of advanced biogas plant

Power generation and purified gas supply business

by high temperature fermentation system which

utilizes solubilization tank

Basic flow for construction of biogas power plant

Of all the steps in the following process, STEP 3. Study for methane gas generation Rate, is particularly important. Equipment will be selected based on the results of this study and a more specific rate of return can be calculated.

STEP 1Secure stable suppliers of main raw materials.

STEP 2Blending of raw materials

It is necessary to ensure other raw materials that can be blended in the vicinity of the suppliers of main raw materials, since a stable amount of electricity can be generated with a mix of other raw materials, rather than a single type.

Example: Cattle excrement or swine excrement 60% + food residue 20% + Sake/shochu or manufacturing process residue 10% + bacteria bed 10%, etc.

STEP 3Study for methane gas generation rate

A study for methane gas generation rates for each raw material that is intended for use is carried out to verify the most high-efficiency blending ratio of raw materials.

STEP 4-1Selection of equipment

The most optimal equipment are selected since the most suited equipment depends on the raw materials that are intended for use.

STEP 4-2Selection of plant site

The most optimal plant site must be selected, taking into account the transportation costs from each raw material supplier.

STEP 5Designing systems

Formation model for a regional recycling biogas energy system

New regional industries can be created by“electricity”, “purified methane gas”, “waste heat&CO2” and “liquid fertilizer”that are emitted from a biogas plant.

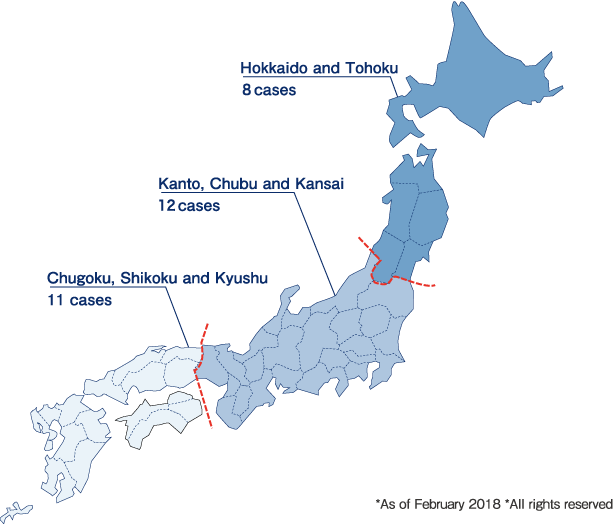

Further installations (planned)