- Biomass Power Generation

(Wood and Other Dried Materials) - Organic Biomass Operations

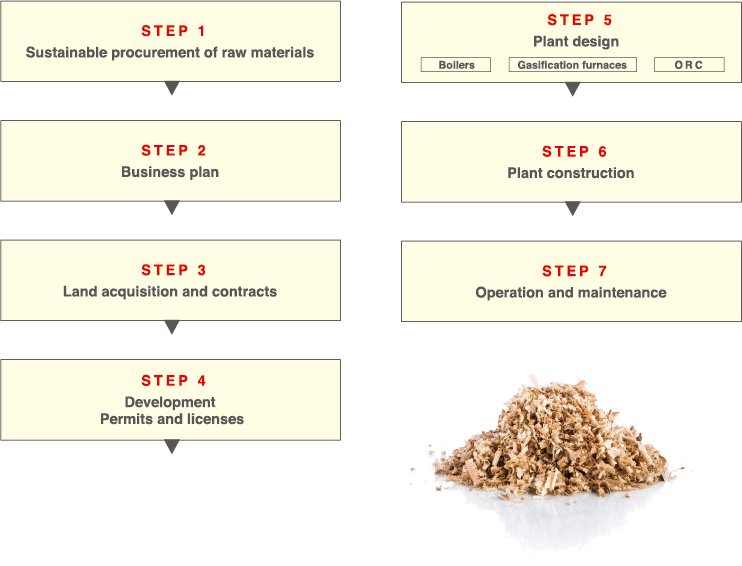

- Business Scheme for

Wood Biomass Power Generation - Selection in Plant Design

- Application of “AI” technology

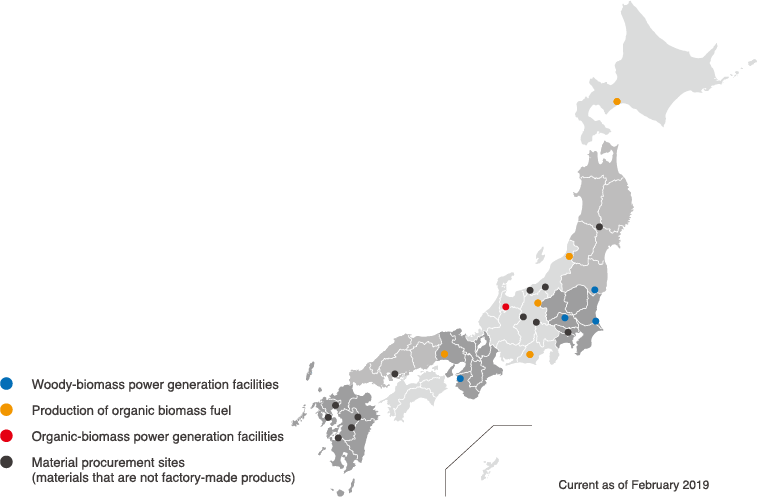

in Biomass by PR-AZ - Sites of Implementation of Full Range of Biomass Operations (Including Ones in Planning Stage) and Material Procurement

Vitalizing the regional economy and production activities by regional energy industry

Our wood and dried biomass power generation are structured by combining unused biomass resources produced

by local manufacturing and the like with the latest technologies and methods, thereby achieving economically

rational power generation and heat utilization. With agriculture, forestry, and fishery industries, foodstuff-related

industries, and unused local biomass, we can achieve biomass power generation of 2 MW or less by appropriately

addressing the issues related to use of each of these sources.

Business Scheme for Wood Biomass Power Generation

Selection in Plant Design

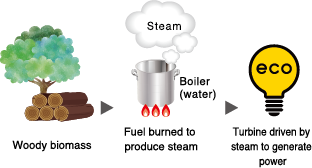

Boilers

Whereas fossil-fuel boilers use such fuels as fuel oil A(Jis), kerosene, or LP gas, biomass boilers use wood and dried biomass. The boiler burns the biomass, producing steam and

hot water as drive force and a source of energy. Shifting from conventional fossil fuels to biomass energy makes possible vast reductions of CO2 emission.

As Fossil-fuel prices are also subject to steep increases, employing our expertise to make use of unused biomass from

the local area and industrial fields is relatively effective in terms of costs as well.

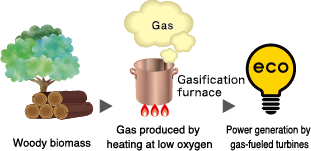

Gasification Furnaces

Chipped or pelletized woody biomass is heated in a gasification furnace in a low-oxygen state, breaking it down into carbon and gas by means of pyrolysis and reduction reactions. The system generates power using engines fueled by this gas.

– High power-generation efficiency even at a small scale

– A system eliminating tar, which is a major factor impeding power generation, thereby achieving stable usage of diverse woody materials

– Simple equipment and small installation footprint.

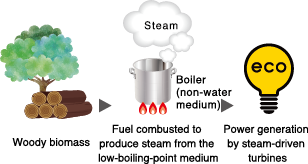

Organic Rankine Cycle (ORC)

This uses the same power-generation system as steam turbines, but the thermal medium is not water (steam), but instead a medium that has a low boiling point (such as silicone oil). This is evaporated at a temperature lower than that of boiling water, driving a turbine to generate power. As cogeneration supplying both heat and electricity, it makes possible use of both hot water and low-pressure steam.

– High power-generation efficiency even at a small scale

– Low usage pressure of the thermal medium, ensuring safety

– Low mechanical stress and no turbine corrosion, reducing the maintenance burden

Application of “AI” technology in Biomass by PR-AZ

A factor that impedes suitable use of local-region biomass is the inability to

achieve accurate assessment and control of type, quality, and quantity. At PR-AZ,

we regard such activities as biomass power generation, heat utilization, and fuel

production as operations of “producing energy resources of stable quality from a

broad range of variable materials.”

In this production of energy resources, we make use of the technologies of Artificial

Intelligence (AI) and the Internet of Things (IoT) from material procurement through

to manufacturing and fluctuations that include the type, quality, and quantity of the

material as well as weather, thereby stabilizing production control, logistics control,

and other tasks. We have begun actual industrial implementation, achieving major benefits.

Sites of Implementation of Full Range of Biomass Operations

(Including Ones in Planning Stage)

and Material Procurement

Organic biomass operations are energy operations of the future that will revolutionize the Industrial configuration

PR-AZ aims to create a recycling-oriented business model with links to industrial structure. Sources of energy

from materials created in local regions are used, and these energy sources are supplied to the local regions.

We believe organic biomass operations to be an optimal tool for this recycling-oriented business model

based on local production for local consumption. We are actively pursuing organic biomass operations.

Issues

Issues in Biomass Power Generation

– Uneven balance between the expanding market scale of biomass power generation and the supply of raw materials

(chiefly wood chips and palm-kernel shells [PKS])

– High susceptibility of biomass fuel to market fluctuations

(balance of supply and demand, material market prices, material types)

– Unstable material quality

– Difficulty in power generation due to difficulty in ensuring stable long-term supply of materials

Issues in Industry Structure

– Increased waste treatment due to diversification and expansion of lifestyle models and diversification of

food consumption

– Compliance with increasingly stricter recycling laws

– Worldwide environmental protection growing every more difficult day by day

– Living environment

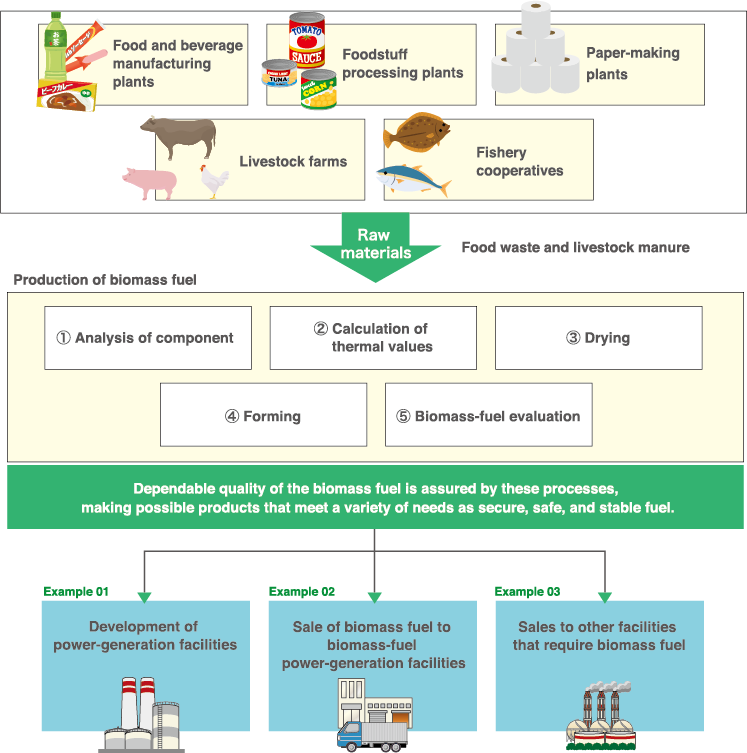

Efforts by PR-AZ

? Solutions to meet the challenges of industrial issues

We take waste materials emitted by various industries and

transform them into high-quality biomass fuel which is distributed

into the economy.

? Adaptation to widely diversifying operation models

We offer optimal solutions to accommodate a diverse array of

needs, from power generation to business operations for supply as

biomass fuel, boosting efficiency in manufacturing plants and

in agricultural and fisher-related operations, and even overall

coordination of business operations.

? Secure, safe, and stable supply models

The raw materials are procured from a various range of industries

in Japan, making possible accurate traceability as well as enabling

the stable supply of secure and safe raw materials that are resistant

to the impact of overseas market conditions.

? Creation of a supply network covering all regions

of Japan

From Hokkaido in the north to Kyushu and Okinawa in the south,

we are moving ahead with the construction of production centers

for biomass fuel in all areas of Japan. We are configuring a supply

network that meets the needs of biomass power-generation facilities

dispersed throughout the country and operators that use biomass fuel.

? Feed-in Tariffs (FIT)

The price assurance of the feed-in tariffs (FIT) established by

Japan’s Ministry of Economy, Trade, and Industry enables optimal

utilization in business operations that use FIT.

? Creation of new business models through research

and development

With respect to the modality of business models in the area

of biomass operations, we conduct research and development

in collaboration with specialized entities, centering on universities,

and collect data for creating new business models.

Scheme of Biomass Operations

The needs for biomass fuel are diverse.

PR-AZ can offer solutions that meet your needs.